Stainless Steel Pipe: A Comprehensive Guide to Types, Sizes, and Applications

stainless steel pipe Introduction

Stainless steel pipes are essential components for a wide range of industries, due to their durability, corrosion resistance, and versatility. Stainless steel pipes are widely used in construction projects, designing piping systems, and manufacturing industrial equipment.

In this blog, we will explore information about stainless steel pipes, including its types, sizes (including 2-inch, 3-inch, and 4-inch stainless steel pipes), properties, applications, and how to choose the right stainless steel pipe factory or wholesaler.

walmay steel:High quality stainless steel pipe manufacturers

What Are Stainless Steel Pipes?

Stainless steel pipes are hollow cylindrical tubes made of alloys of iron, chromium, and other elements such as nickel and molybdenum.

These pipes are widely used to transport fluids, gases, and other materials due to their high strength, corrosion resistance, and resistance to high temperatures and pressures.

Stainless steel pipes come in a variety of sizes, including 2-inch, 3-inch, and 4-inch stainless steel pipes, as well as special types such as corrugated stainless steel pipes.

Types of Stainless Steel Pipes

walmaysteel stainless steel pipes are available in various types, each suited for specific applications.

Stainless steel pipes by grade

304 Stainless Steel Pipe: The most in demand, with excellent corrosion resistance and formability. Suitable for pipelines, food processing and chemical industries.

316 Stainless Steel Pipe: The addition of molybdenum makes it have excellent resistance to chlorides and acids. Suitable for marine environments, medical equipment and chemical processing.

430 Stainless Steel Pipe: An affordable choice with good corrosion resistance, commonly used in appliances and automotive exhaust systems.

Duplex Stainless Steel Pipe: Combines high strength and corrosion resistance, suitable for heavy industrial applications such as oil and gas pipelines.

stainless steel pipe sizes

2 inch stainless steel pipe: Commonly used for plumbing, HVAC systems, and small industrial applications.

3 inch stainless steel pipe: Suitable for medium-sized industrial and construction projects.

4 inch stainless steel pipe: Suitable for large industrial applications, including water treatment plants and chemical processing facilities.

Corrugated stainless steel pipe: Suitable for decorative

Stainless steel pipes by surface treatment

Stainless steel pipes are classified by surface treatment

Polished: smooth and reflective, customers can choose when it is used for decorative and sanitary applications.

Matte: non-reflective and durable, suitable for industrial use.

Sandblasting: a textured surface often seen in architectural applications.

Properties of Stainless Steel Pipes

The physical, chemical and mechanical properties of stainless steel pipes are of high quality, meeting the different needs of customers.

Physical properties of stainless steel pipes

Physical properties of stainless steel pipes

Density: about 7.93 g/cm³.

Melting point: about 1400-1450°C.

Thermal conductivity: low, about 15 W/m·K.

Magnetic properties: Austenitic grades (e.g. 304, 316) are generally non-magnetic, while ferritic and martensitic grades (e.g. 430, 410) are magnetic.

Chemical Properties of Stainless Steel Tubes

Corrosion Resistance: High resistance to rust and oxidation due to the presence of chromium.

Acid and Alkali Resistance: Performs well in acidic and alkaline environments, especially grades such as 316.

Hygiene: Non-porous surface prevents bacterial growth, ideal for the food and medical industries.

Manufacturing Process of Stainless Steel Pipes

Walmay Steel’s stainless steel pipes usually go through 8 steps before they reach our customers.

Raw material selection: High-quality stainless steel alloys are selected based on the customer’s required performance.

Forming: The steel is formed into a cylindrical shape using methods such as extrusion or welding.

Welding: For welded pipes, the edges are joined using techniques such as TIG or laser welding.

Heat treatment: Annealing to relieve internal stress and improve ductility.

Surface treatment: Processes such as pickling, polishing, or passivation to achieve the required finish.

Cutting: The pipe is cut into the length required by the customer, such as 2-inch, 3-inch, or 4-inch stainless steel pipes.

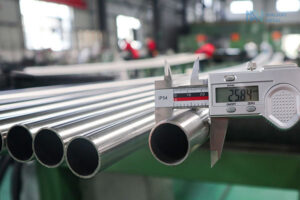

Quality inspection: Strict tests are performed on thickness, diameter, and surface quality.

Packaging: The pipes are carefully packaged to prevent damage during transportation.

Applications of Stainless Steel Pipes

walmay steel stainless steel pipes are used in a wide range of industries:

Plumbing: Water supply and drainage systems.

Oil and Gas: Pipelines and drilling equipment.

Food Processing: Sanitary tubing for transporting liquids and gases.

Construction: Structural components and HVAC systems.

Medical: Surgical instruments and sterilization equipment.

Automotive: Exhaust systems and fuel lines.

Industrial: Chemical processing and water treatment plants.

stainless steel pipe conclusion

Our customers often inquire about stainless steel pipes due to their durability, versatility, and aesthetics.

When choosing quality stainless steel tubes, it is important to choose a reliable stainless steel pipe supplier. Walmay is a reliable partner that provides quality stainless steel pipe tubes that meet the highest standards.

Contact Walmay today to find the perfect solution for your needs.

Tabs:stainless steel pipe ,tainless steel pipes,316 Stainless Steel Pipe

Table of Contents

Recent Posts

-

U.S. Stainless Steel Tariffs Jump to 50% - How Companies Are Adapting01 8 月 2025

U.S. Stainless Steel Tariffs Jump to 50% - How Companies Are Adapting01 8 月 2025 -

Global Steel Output Drops 5.8% in June - India Bucks the Trend31 7 月 2025

Global Steel Output Drops 5.8% in June - India Bucks the Trend31 7 月 2025 -

Alleima's New Super Duplex Steel Fights Urea Plant Corrosion29 7 月 2025

Alleima's New Super Duplex Steel Fights Urea Plant Corrosion29 7 月 2025 -

310S vs 304 Stainless Steel Pipes: Which Should You Choose?28 7 月 2025

310S vs 304 Stainless Steel Pipes: Which Should You Choose?28 7 月 2025

Have Any Question?

High-quality manufacturers in the stainless steel industry, feel free to ask