Stainless Steel Metric Tubing: 304 vs 316 vs 904L Pipes Compared

Why Stainless Steel Metric Tubing?

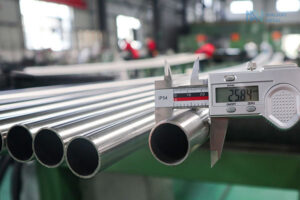

Stainless steel metric tubing is essential in industries ranging from chemical processing to aerospace, offering corrosion resistance, durability, and high strength-to-weight ratios. Whether you need 304 stainless steel pipe for food-grade applications or 316 stainless steel tubing for marine environments, selecting the right alloy is critical.

This guide explores the key differences between 304, 316, and 904L stainless steel pipes, their applications, and how to choose the best metric stainless steel tubing for your project.

Types of Stainless Steel Metric Tubing

304 Stainless Steel Pipe (SS 304)

Properties:

✔ Holds up like a champ against rust and chemicals

✔ High formability and weldability

✔ Cost-effective for general use

Applications:

When ordering 304 stainless steel pipes, specify wall thickness (e.g., SCH 40)

Food & beverage processing

Architectural structures

Automotive exhaust systems

Keyword Tip: “stainless steel pipe SS 304” is a high-volume search term for industrial buyers.

316 Stainless Steel Tubing (SS 316)

Properties:

✔ Superior chloride resistance (ideal for saltwater)

✔ Higher nickel & molybdenum content than 304

✔ Excellent for chemical processing

Applications:

Marine equipment;Pharmaceutical tubing;Coastal construction

904L Stainless Steel Pipe (Premium Alloy)

“According to NACE MR0175, 904L is approved for sour gas service.”

Properties:

✔ Extreme corrosion resistance (acidic/chloride environments)

✔ High nickel & copper content

✔ Used in aggressive chemical industries

Applications:

Oil & gas pipelines;Sulfuric acid handling;Heat exchangers

Walmay Steel Supplier Note: “904L stainless steel pipe suppliers” is a high-intent keyword for bulk buyers.

How to Choose the Right Metric Stainless Steel Tubing

Now that you know the types, let’s dive into how to select the right one for your project.

Key Selection Factors:

✔ Environment (e.g., marine = 316, acidic = 904L)

✔ Budget (304 is most affordable, 904L is premium)

✔ Fabrication Needs (You can weld 304 more easily than 316/904L)

Pro Tip:

“For high-temperature applications, check if your stainless steel 304 pipes meet ASTM A312 standards.”

Conclusion: Which Stainless Steel Pipe is Best?

Choosing Stainless Steel Tubing:

1. Is the budget a priority? → 304

2. Exposure to saltwater/chemicals? → 316

3. Handling concentrated acids? → Find 904L Pipe Suppliers Near You

Where to Buy Stainless Steel Metric Tubing?

Need a Quote? Contact trusted 904L stainless steel pipe suppliers, Walmay Steel, today!

Tabs: metric stainless steel tubing, 304 stainless steel pipe ,316 stainless steel pipe,904l stainless steel pipe suppliers

Table of Contents

Recent Posts

-

2205 vs 2507 Duplex Stainless Steel: Choosing Your Industrial Champion24 7 月 2025

2205 vs 2507 Duplex Stainless Steel: Choosing Your Industrial Champion24 7 月 2025 -

430 Stainless Steel: The Cost-Effective Workhorse You Should Know About22 7 月 2025

430 Stainless Steel: The Cost-Effective Workhorse You Should Know About22 7 月 2025 -

Alleima's New Super Duplex Stainless Steel Revolutionizes Urea Industry21 7 月 2025

-

304 vs 316 Stainless Steel: Which Should You Choose?18 7 月 2025

304 vs 316 Stainless Steel: Which Should You Choose?18 7 月 2025

Have Any Question?

High-quality manufacturers in the stainless steel industry, feel free to ask