Stainless Steel Diamond Plate vs. Checker Plate: Key Differences and Applications

Stainless Steel Diamond Plate vs. Checker Plate: Key Differences and Applications

Regarding textured stainless steel plates, Walmay Steel found that among the products required by customers,stainless steel diamond plate and stainless steel checker plate, there are two products that customers need.

These two products can be used interchangeably, but they have different characteristics and are suitable for different purposes.

In this article, Walmay Steel will use rich theories to show our customers:

The key differences between stainless steel diamond plate and checker plate

Their unique applications in various industries

Common stainless steel plate grades like 304 and 316

Standard sizes including 1/4 stainless steel plate

Current stainless steel plate price trends

Alternative options like stainless steel perforated plate

What is Stainless Steel Diamond Plate?

Stainless steel diamond plate features a raised diamond pattern on one side, providing excellent slip resistance while maintaining the corrosion-resistant properties of standard stainless steel plates. This textured surface is created through a cold rolling process that embosses the pattern into the stainless steel metal plate.

Stainless Steel Diamond Plate Common specifications:

Thicknesses: 1/4 in stainless steel plate and thinner gauges

Popular grades: 304 stainless steel plate and 316 stainless steel plate

Surface finish: Brushed or polished

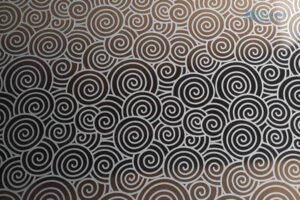

What is Stainless Steel Checker Plate?

Stainless steel checker plate (sometimes called tread plate) features a raised checkerboard pattern of small squares or rectangles. Like its diamond-patterned counterpart, it offers slip resistance but with a different aesthetic appeal.

Stainless Steel Checker Plate Key characteristics:

Pattern options: Small check, large check, or custom designs

Material options: Stainless steel steel plate in various grades

Common uses: Stair treads, truck beds, and industrial flooring

Key Differences Between Diamond Plate and Checker Plate

| Feature | Diamond Plate | Checker Plate |

| Pattern | Raised diamond shapes | Square/rectangular raised pattern |

| Slip Resistance | Excellent | Good |

| Aesthetic | Industrial look | More uniform appearance |

| Common Thickness | 1/4 stainless steel plate common | Thinner gauges more prevalent |

| Cost | Slightly higher stainless steel plate price | Typically more affordable |

Applications of Diamond and Checker Plates

Stainless Steel Diamond Plate Uses:

Industrial flooring – Slip-resistant surfaces in factories

Stair treads – Safety in commercial buildings

Truck beds and trailers – Durable cargo areas

Architectural accents – Decorative wall panels

Stainless Steel Checker Plate Applications

Vehicle running boards – Improved footing

Loading ramps – Secure footing for equipment

Kitchen equipment – Slip-resistant food prep areas

Decorative elements – Modern interior design features

Choosing the Right Grade: 304 vs. 316 Stainless Steel Plates

Both stainless steel diamond plate and checker plate are available in different stainless steel plate grades:

304 Stainless Steel Plate: The most common grade for general use; Excellent corrosion resistance; Cost-effective option; Ideal for indoor applications.

316 Stainless Steel Plate: Superior corrosion resistance; Contains molybdenum for harsh environments; Better for marine or chemical exposure; Higher stainless steel plate price.

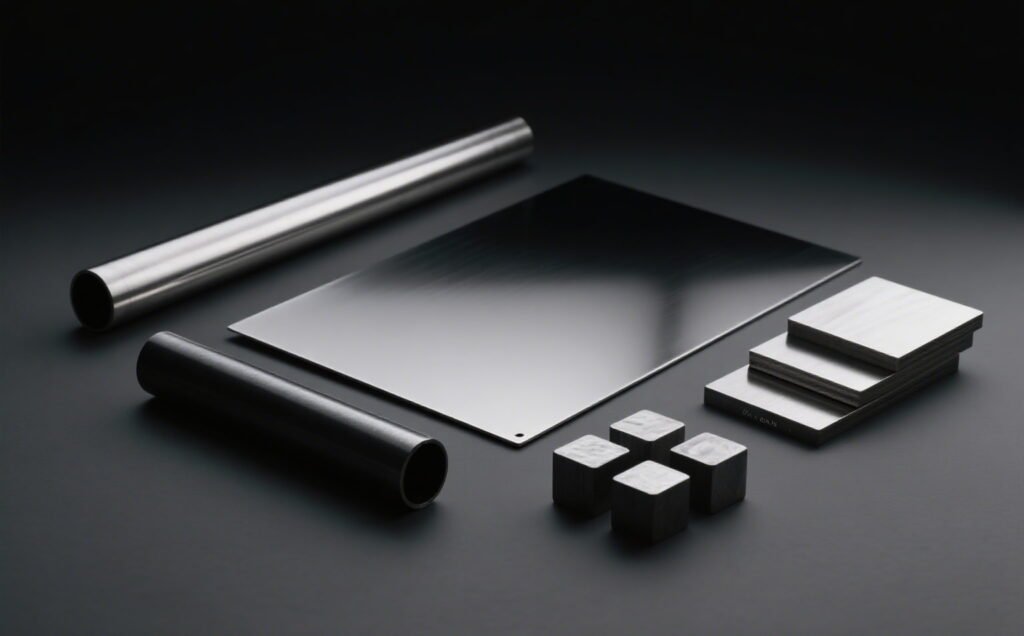

Sizing Options: 1/4 in Stainless Steel Plate vs Thin Sheets

Both plate types come in various thicknesses:

Heavy-duty: 1/4 stainless steel plate (6.35mm)

Medium-duty: 3/16″ (4.76mm)

Light-duty: 1/8″ (3.18mm) and thinner

The 1/4 in stainless steel plate is particularly popular for:Industrial flooring;Heavy equipment protection;Structural applications;

Thinner gauges work well for:Decorative panels;Vehicle trim;Light-duty walkways.

Alternative Options: Stainless Steel Perforated Plate

When customers need some textured stainless steel plates, stainless steel perforated plates can also meet customer requirements. This plate has a variety of hole patterns and sizes, lightweight structure while maintaining strength, and has similar corrosion resistance to solid stainless steel plates.

Conclusion: Choosing Between Diamond and Checker Plateorated Plate

When selecting between stainless steel diamond plate and checker plate:

Safety needs: Diamond offers better slip resistance

Aesthetic preferences: Checker plate provides a more uniform look

Budget: Checker plate typically costs less

Environment: 316 grade for harsh conditions

For your next project, consult with a reputable supplier walmay steel to discuss stainless steel plate grades, available sizes like 1/4 in stainless steel plate, and current stainless steel plate price options to find the perfect solution for your needs.

Tabs:Stainless Steel Perforated Plate,Stainless Steel Diamond Plate,Stainless steel checker plate

Recent articles:

Table of Contents

Recent Posts

-

China’s Stainless Steel Trade Shifts: Exports Rise as Imports Hit 64-Month Low22 8 月 2025

China’s Stainless Steel Trade Shifts: Exports Rise as Imports Hit 64-Month Low22 8 月 2025 -

Indonesia’s Nickel Exports in July 2025: China Remains Top Destination21 8 月 2025

Indonesia’s Nickel Exports in July 2025: China Remains Top Destination21 8 月 2025 -

Russia’s Stainless Steel Market: Q1 2025 Consumption Dips Slightly, Import Reliance Grows20 8 月 2025

Russia’s Stainless Steel Market: Q1 2025 Consumption Dips Slightly, Import Reliance Grows20 8 月 2025 -

Indonesia Dominates Global Nickel Supply - What It Means for Stainless Steel18 8 月 2025

Indonesia Dominates Global Nickel Supply - What It Means for Stainless Steel18 8 月 2025

Have Any Question?

High-quality manufacturers in the stainless steel industry, feel free to ask