Shanhe Road, Anzhen

Wuxi, Jiangsu

yoyo@walmaygroup.com

24/7 Customer Support

+8615251428655

Mon - Fri: 9:00 - 17:30

Wuxi, Jiangsu

24/7 Customer Support

Mon - Fri: 9:00 - 17:30

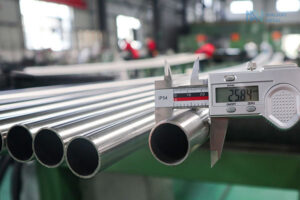

A stainless steel pipe is a hollow, long, round steel bar, usually made of austenitic stainless steel (such as 304 stainless steel pipe, 316 stainless steel pipe

or martensitic stainless steel (such as 410, 420).

Stainless steel pipes have excellent corrosion resistance, high strength and good processing properties, and are suitable for manufacturing pipes, structural parts and decorative parts.

Stainless steel pipes are a material widely used in petrochemical, food processing, architectural decoration, medical equipment and other fields.

The chemical composition of stainless steel pipes is the basis of their excellent performance. (taking 304, 316, 410, 430 as examples):

| element | Fe | Cr | Ni | Mo | C | Mn | Si | P | S |

| 304 (%) | balance | 18.0 – 20.0 | 8.0 – 10.5 | – | ≤0.08 | ≤2.0 | ≤1.0 | ≤0.045 | ≤0.03 |

| 316 (%) | balance | 16.0 – 18.0 | 10.0 – 14.0 | 2.0 – 3.0 | ≤0.08 | ≤2.0 | ≤1.0 | ≤0.045 | ≤0.03 |

| 410 (%) | balance | 11.5 – 13.5 | ≤0.75 | – | 0.08 – 0.15 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 |

| 430 (%) | balance | 16.0 – 18.0 | ≤0.75 | – | ≤0.12 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 |

Stainless steel pipes have excellent mechanical properties and can meet the needs of a variety of industrial applications. (Take 304, 316, 410, 430 as examples):

| Performance | 304 | 316 | 410 | 430 | Test standards |

| Tensile Strength | ≥515 MPa | ≥515 MPa | ≥480 MPa | ≥450 MPa | ASTM A276 |

| Yield Strength | ≥205 MPa | ≥205 MPa | ≥275 MPa | ≥205 MPa | ASTM A276 |

| Elongation | ≥40% | ≥40% | ≥20% | ≥22% | ASTM A276 |

| Hardness | ≤90 HRB | ≤90 HRB | ≤95 HRB | ≤89 HRB | ASTM E18 |

| Impact Toughness | ≥100 J | ≥100 J | ≥50 J | ≥50 J | ASTM A370 |

| Density | 7.93 g/cm³ | 7.98 g/cm³ | 7.75 g/cm³ | 7.70 g/cm³ | – |

The physical properties of stainless steel pipes are important indicators of their applicability (taking 304, 316, 410, and 430 as examples):

| Performance | 304 | 316 | 410 | 430 |

| Density) | 7.93 g/cm³ | 7.98 g/cm³ | 7.75 g/cm³ | 7.70 g/cm³ |

| Melting Point | 1399°C – 1427°C | 1371°C – 1399°C | 1480°C – 1530°C | 1427°C – 1510°C |

| Thermal Expansion | 17.3 μm/m·°C (20°C-100°C) | 16.5 μm/m·°C (20°C-100°C) | 10.4 μm/m·°C (20°C-100°C) | 10.4 μm/m·°C (20°C-100°C) |

| Thermal Conductivity | 16.2 W/m·K (100°C) | 16.3 W/m·K (100°C) | 24.9 W/m·K (100°C) | 26.0 W/m·K (100°C) |

| Electrical Resistivity | 0.72 μΩ·m (20°C) | 0.74 μΩ·m (20°C) | 0.57 μΩ·m (20°C) | 0.60 μΩ·m (20°C) |

| Magnetic Permeability | 1.02 | 1.02 | 1.02 | 1.02 |

Stainless steel pipes have a wide range of wall thicknesses that can be customized according to customer needs:

Thin-walled pipes: 0.5mm-3.0mm, suitable for lightweight and low-pressure environments.

Medium-thick walled pipes: 3.0mm-12.0mm, suitable for general industrial applications.

Thick-walled pipes: 12.0mm-50.0mm, suitable for high-pressure and high-temperature environments.

Classification by material:

Austenitic stainless steel pipes: such as 304 and 316, with good corrosion resistance, suitable for most environments.

Martensitic stainless steel pipes: such as 410 and 420, with high hardness, suitable for wear-resistant parts.

Ferritic stainless steel pipes: such as 430, with low cost, suitable for general use.

Classification by manufacturing process:

Seamless stainless steel pipes: manufactured by hot rolling or cold drawing process, suitable for high pressure and high temperature environment.

Welded stainless steel pipes: manufactured by welding process, with low cost, suitable for general use.

Stainless steel pipes are widely used in the following fields:

Petrochemical industry: used to manufacture pipes, valves, pump bodies and storage tanks.

Food processing: used to manufacture food processing equipment, storage tanks and pipes.

Architectural decoration: used to manufacture building curtain walls, railings, doors and windows and decorative parts. Medical equipment:

Used to manufacture surgical instruments, medical containers and laboratory equipment.

Automobile manufacturing: used to manufacture exhaust systems and fuel systems.

SWalmay Steel, as a stainless steel pipe supplier that values quality,tainless steel pipes comply with the following international standards:

ASTM A312: Seamless and welded austenitic stainless steel pipes.

ASTM A213: Seamless ferritic and austenitic alloy steel pipes for boilers, superheaters and heat exchangers.

ASTM A269: Seamless and welded austenitic stainless steel pipes for general purposes.

JIS G3459: Stainless steel pipes.

GB/T 12771: Stainless steel welded steel pipes for fluid transportation.

Acidic environment: such as sulfuric acid, hydrochloric acid, phosphoric acid, etc., excellent corrosion resistance.

Alkaline environment: such as sodium hydroxide, potassium hydroxide, etc., excellent corrosion resistance.

High temperature oxidation environment: It can still maintain good oxidation resistance at high temperature, suitable for boilers and heat exchangers.

Stainless steel

High cost: The production cost of stainless steel pipes is high, resulting in relatively high prices.

Thermal expansion problem: Due to the large thermal expansion coefficient of stainless steel pipes, when the temperature changes, it may cause deformation and stress concentration of the pipe, thereby affecting the stability and life of the pipe.

Welding problem: Porosity is easily generated during the welding process, which may reduce the strength and sealing of the pipe.

Stainless steel pipes can be used for drinking water and are a healthy choice for drinking water at home.

Stainless steel pipes do not contain harmful substances, such as lead-free and PVC-free, ensuring safe water use at home.

Stainless steel pipes will not breed green algae, dirt, scale, etc., avoiding secondary pollution in the pipes and keeping the water clean.

304 food-grade stainless steel pipes comply with GB/T 29038-2012 (drinking water pipes) standards. The migration of heavy metals such as nickel, sulfur, phosphorus, lead, and chromium is within the standard range. Long-term use will not cause scaling and will not be easily contaminated by bacteria.

Material: 304, 304L, 316, 316L, 321, 347, 410, 420, 430, etc.

Standard: ASTM A312, ASTM A213, ASTM A269, JIS G3459, GB/T 12771

Shape: seamless pipe, welded pipe

Outer diameter range: 6mm-1200mm

Wall thickness range: 0.5mm-50mm

Length range: 1000mm-12000mm (custom length supported)

If you have any questions, please use the form below to send us a message or contact Walmay Metal’s office location.

A supplier focusing on the stainless steel industry

Copyright © 2024. All rights reserved.